Why Deep Mould's Metal Fabricators are Experts in Injection Molded Prototypes

For businesses in need of metal fabricators specializing in injection molded prototypes, Deep Mould is the go-to company that delivers outstanding results. With years of experience and a team of highly skilled professionals, Deep Mould has solidified its position as a leader in the industry. In this article, we will explore why their expertise and attention to detail make them the best choice for your prototyping needs.

The Process of Injection Molded Prototypes

The process of creating injection molded prototypes requires precision, knowledge, and cutting-edge technology. Deep Mould understands the intricacies involved in creating functional prototypes that withstand rigorous testing. They leverage their expertise to ensure each prototype is of the highest quality.

Starting with the design phase, Deep Mould's team of talented engineers collaborates closely with clients to understand their specific requirements. This collaborative approach ensures that the final product meets the client's expectations while providing valuable insights to enhance the design. Deep Mould's engineers utilize advanced software to create detailed 3D models and conduct thorough simulations to identify any potential design flaws.

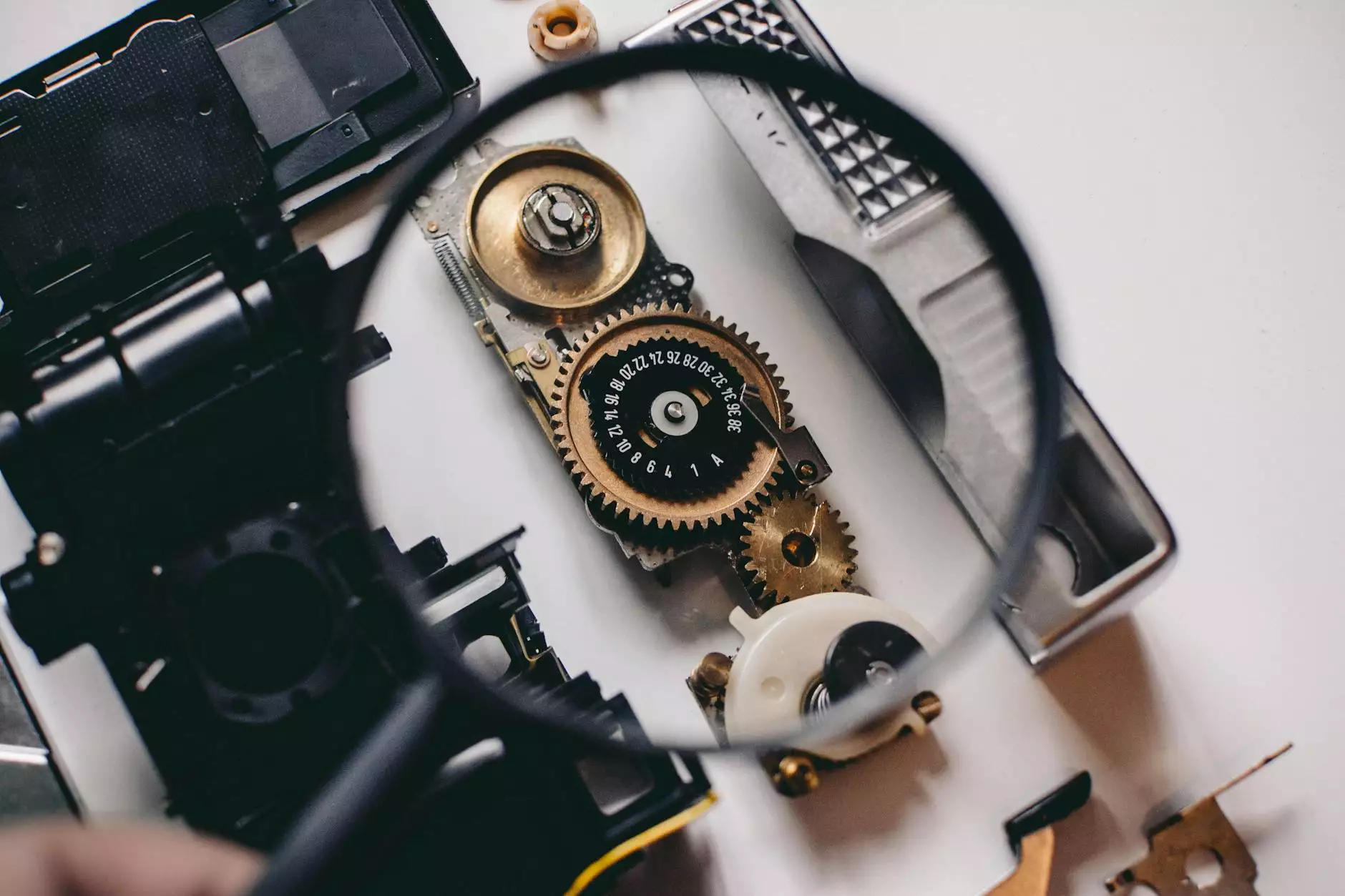

Once the design is approved, Deep Mould's metal fabricators take over, employing their extensive knowledge of various materials and injection molding techniques. From plastic to metal, the skilled fabricators select the optimal material for the prototype. They leverage their expertise to determine the most suitable mold design and carefully consider factors such as material flow, cooling time, and shrinkage.

The fabrication process itself is a combination of precision machinery and skilled craftsmanship. Deep Mould's technicians meticulously set up the injection molding machines, ensuring precise temperature and pressure control. They monitor the process closely, making necessary adjustments along the way to guarantee consistent and accurate results.

The Benefits of Deep Mould's Injection Molded Prototypes

Deep Mould's injection molded prototypes offer numerous benefits that give their clients a competitive edge in their respective industries. Let's explore some of these benefits:

1. Cost and Time Savings

By choosing Deep Mould for your injection molded prototype needs, you can save significant cost and time compared to traditional manufacturing methods. The streamlined fabrication process, coupled with efficient material usage, reduces production time and minimizes waste.

2. High Precision and Accuracy

With Deep Mould's state-of-the-art machinery and experienced technicians, each injection molded prototype is produced with exceptional precision and accuracy. This ensures that the final product reflects the intended design, allowing for efficient testing and validation.

3. Versatility in Material Selection

Deep Mould's metal fabricators possess a wealth of knowledge when it comes to material selection. Whether your project requires plastic, aluminum, steel, or other materials, Deep Mould can recommend the optimal choice based on your specific requirements. This flexibility allows for a wide range of applications and industries to benefit from their expertise.

4. Prototype Validation and Testing

Deep Mould understands the importance of thorough prototyping and testing. Their injection molded prototypes undergo rigorous validation processes to ensure they meet the intended functionality and performance. This attention to detail allows for efficient iterations and improvements during the development stage.

Success Stories at Deep Mould

Countless businesses have already benefited from Deep Mould's expertise in injection molded prototypes. Let's take a closer look at a few success stories:

1. Electronics Industry

Deep Mould partnered with a leading electronics company to create injection molded prototypes for their innovative product line. The ability to produce precise and functional prototypes allowed the client to optimize their design and significantly reduce time to market. The final product received accolades for its superior quality and performance.

2. Automotive Industry

An automotive manufacturer turned to Deep Mould to develop injection molded prototypes for a crucial part in their new vehicle model. Deep Mould's expertise in material selection and mold design resulted in prototypes that met stringent industry standards. The successful validation of the prototypes helped the client secure a substantial contract for mass production.

3. Medical Device Industry

Deep Mould collaborated with a medical device startup to create injection molded prototypes for their groundbreaking surgical instrument. Deep Mould's precision in fabricating complex prototypes allowed the startup to refine their design and attract significant investor interest. The prototypes played a crucial role in securing necessary funding for further development.

Conclusion

When it comes to metal fabricators specializing in injection molded prototypes, Deep Mould's unparalleled expertise and commitment to excellence make them the top choice. Their meticulous attention to detail, efficient fabrication process, and successful track record set them apart from the competition. By choosing Deep Mould, businesses can confidently bring their ideas to life with high-quality prototypes that pave the way for future success.